18 cultivation layers tank facility installed at Foodiverse, within the framework of the CDTI project.

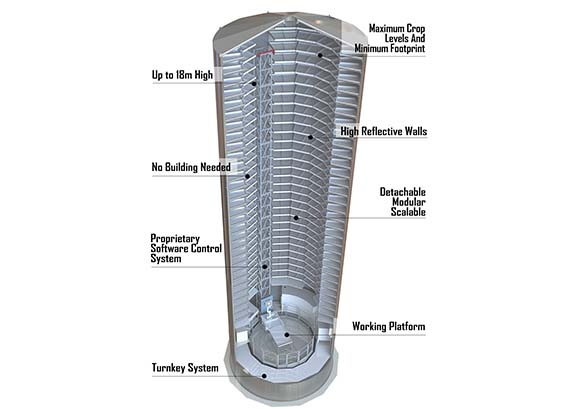

Farmitank is a fully climate-controlled hydroponic farm that integrates an advanced technology to achieve the optimal climatic and lighting conditions that, combined with a perfect mix of nutrients, guarantees the maximum product quality.

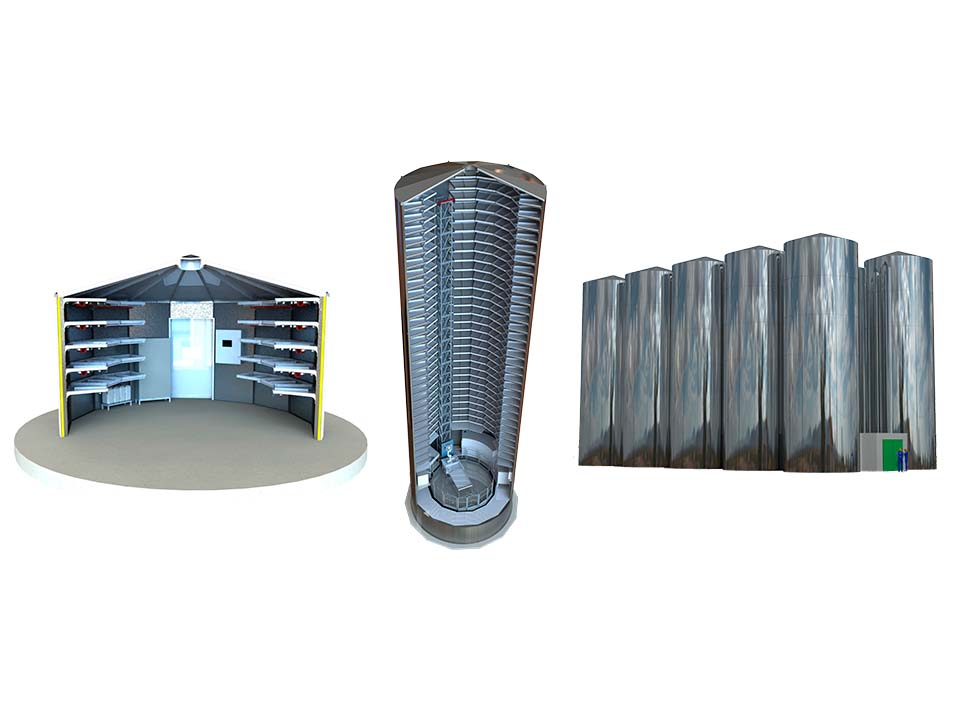

We have patented a new and disruptive design totally different from others on the market. Crops are grown inside an isothermal, modular and scalable stainless-steel tank. This system occupies 40 m2 and there are different models between 3 and 18 meters high, reaching up to 400 square meters of cultivation.

The elevator is a system that makes Farmitank unique. It is a working platform that allows all agricultural tasks to be carried out at each level of crop. This means crop table is easily reachable, minimizing crop trays movements and leading to optimized seedling, transplants and harvests times.

Through its software, Farmitank allows you to control all the growing variables such as lighting, climate, and proper water conditions. This guarantees a fast growth, a high-quality product and easily replicable, regardless of external weather conditions and other environmental factors.

Our growing system is unique. We integrate automatisms which save labour costs such as seeding machines, transplanting robots and herb trimming machines.

Our motto: “We bring the automation to the crop”.

Farmitank is especially designed for growing leafy greens, microgreens and herbs. At our research and development facilities we have tested more than 25 crops varieties with excellent yield results.

We are a company that designs, manufactures and installs the turnkey system. In addition, we study each project individually, considering different factors, such as location or crop varieties, to ensure that the client receives a product tailored to their preferences.

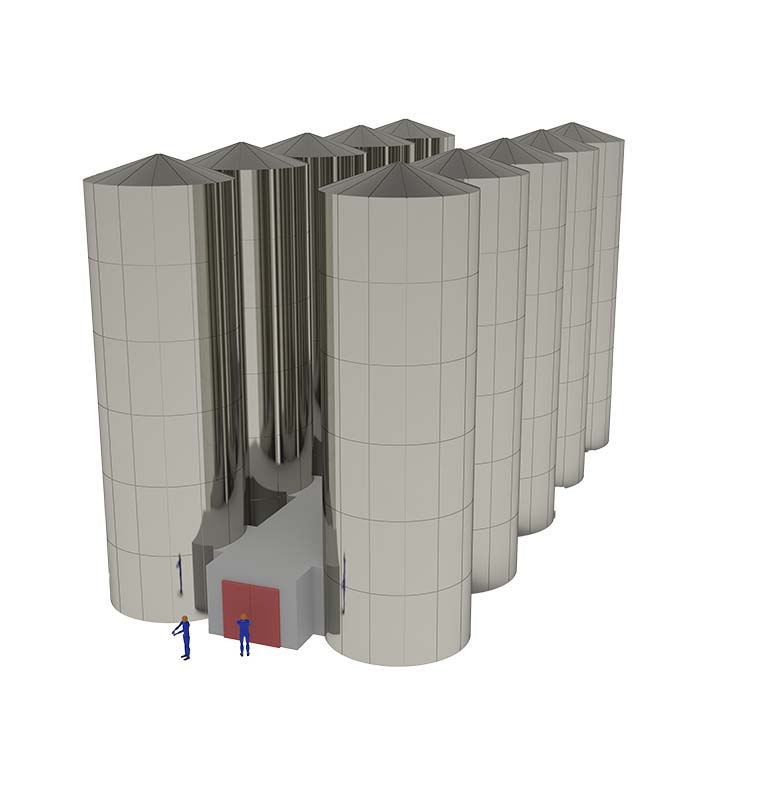

Scalability is one of the main advantages of this system. This quality allows the clients to make a small investment to install a 4-meter-high tank to test the technology and research different varieties. This tank could later be extended to 18 meters, or the installation could be increased with several tanks, once the business plan has been developed and validated on a small scale.

The elevator can integrate automated sowing, transplanting and harvesting systems. In this way, we bring automation to the crop levels, avoiding unproductive labor times to move the plants to a work area further away from the crops.

.jpg)

Install Farmitank next to your processing factory, distribution centre or the consumer area.

Farmitank is scalable, so tanks can be added depending on your needs. Organize tanks by crop or adapt production to market demands.

We use reflectors on each crop level to improve efficiency and lighting efficacy, achieving, also, a high lighting uniformity at the crop table and increasing intensity with the same electrical output. Thanks to this exclusive technique, we have reached as much as 120 kg/m2/year in lettuce.

One tank footprint is 40 m2, multiplying this area by 10 to have up to 400 m2 of cultivation inside an 18-meter high tank with 30 levels. This makes Farmitank the tallest vertical farm in the world.

Easy and quick to assemble and disassemble. In addition, as it is a modular system, it is easily transportable to any part of the world.

The system HVAC is another of our strengths due to vertical ventilation in all its levels. We can also generate different climatic zones inside the same tank.

Monitor your farm thanks to our own software control system design. Remotely control all growing variables and system equipment. It includes follow-up graphs, operation history and alarm or incident notification system.